Consumer Durables

Plastic items are essential in our daily lives, used in various applications from household appliances to furniture, kitchenware, toys and sports & leisure.

Manufacture Products Built to Last

Consumer durables often involve frequent use and require high durability and stability, must endure different temperatures, and even more demanding conditions requiring good mechanical performance.

We offer a broad portfolio of masterbatch and compound for your durable goods, considering ever-changing trends, regulations, and consumer demands as well as various material options.

Where Our Products Make an Impact

- Household appliances

- Food services

- Furniture

- Gardening & power tools

- Toys

- Sports and leisure

Developments in the Consumer Durables Sector

As the consumer durables sector evolves, several key trends are shaping its future. Companies are increasingly focusing on sustainability, durability, and innovation to meet the changing demands of consumers and regulatory requirements. Below, we explore how these developments are influencing the industry.

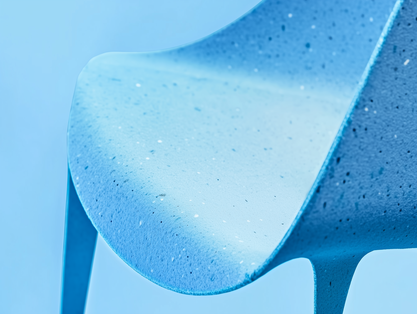

Embracing Sustainability and Durability

The industry is increasingly focusing on sustainability and durability. Companies are now prioritizing EcoDesign by using materials with recycled content. The focus shifts to creating products that withstand the test of time. With the help of our masterbatches and compounds, you can incorporate more recycled content into your products and improve their durability for increased sustainability.

Closing the Loop

There is a growing desire to implement closed-loop systems in the industry. This involves the return of used appliances, which can then be refurbished, recycled, or repurposed. Such initiatives help to minimize waste and promote a circular economy. We formulate our masterbatches and compounds to ensure recycling is guaranteed and made easier.

Connectivity and Smart Appliances

The integration of connectivity in consumer durables is transforming products at their core. Smart appliances are becoming more common, offering convenience and enhanced functionality. This trend is particularly evident in smart cooking, where sensor technologies in ovens allow for features such as temperature control or automatic adjustment of cooking times. With our masterbatches, you equip your materials with the right mechanical and chemical properties to be suitable for use in connected devices.

Digital Transformation

The replacement of mechanical components with digital displays modernizes the appearance of appliances, while also enhancing user experience. Hop on the trend with style thanks to our masterbatches improving the quality and aesthetics of plastic components for digital displays.

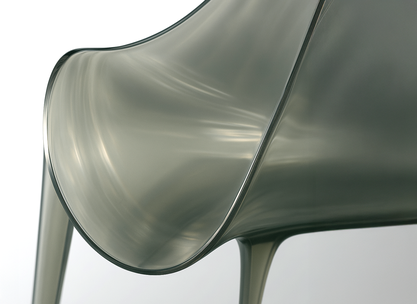

Durability and Design Freedom for Your Consumer Durable Applications

Enhance your product's design versatility with high-quality colors that create distinctive visual appeal. Benefit from long-lasting polymer protection that ensures your products retain their visual and mechanical integrity, even under challenging conditions.

With our solutions, your applications will be able to withstand temperature changes, severe weather, and UV exposure, reducing maintenance needs and prolonging product life. With regulatory-compliant solutions, you can confidently meet industry standards while delivering innovative, sustainable products to the market.

Improving Product Carbon Footprint

Incorporating PCR Material

We have experience in reducing the carbon footprint of non-PCR ABS by incorporating PCR PET into the material. Our technology enables the combination of these incompatible materials while preserving mechanical integrity. By using rPET in your consumer durables applications, you can significantly lower the product’s environmental impact compared to using virgin engineering resins.

Explore Your Material Options

Explore Our Consumer Durables Portfolio

Adding Value Through Expertise and Testing

Regulatory Expertise

The landscape of industrial regulations is complex and varies internationally. With Sukano, you gain access to a team specializing in regulatory affairs and trained to navigate through global regulations. We meticulously assess our formulations against declarable or restricted substances lists, safeguarding your business from potential industrial regulatory pitfalls.

In-House Labs

In our technical center, we produce tailor-made product samples for initial tests. Our equipment allows scale-up sample production and is further enhanced by the analytical center. There, we assess the functional and mechanical properties of the samples and conduct material analysis. Our labs are equipped with high-quality machinery, such as dedicated compounding and injection molding equipment for high-temperature polymers.

Get in Touch with Our Experts!

Your specific needs were not addressed? Tell us about it! Our experts are looking forward to hearing from you and helping you to meet your specific requirements. Contact us now.