Your Global Specialist in Additive and Color Masterbatches and Compounds

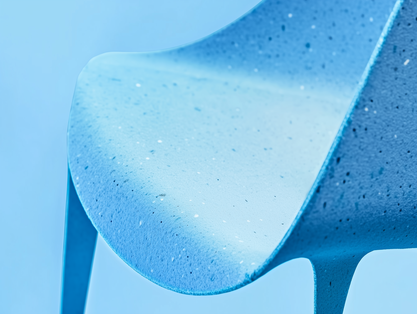

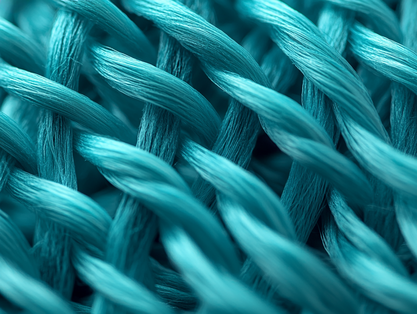

We are driven by expertise, devoting our technical knowledge to developing innovative products and highly specialized solutions for packaging, consumer durables, building and construction, healthcare, and fibers.